Drive-in Racking Systems

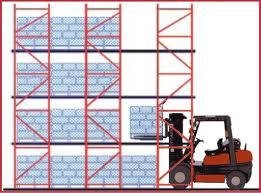

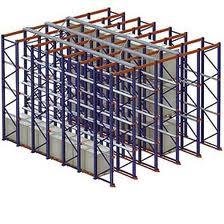

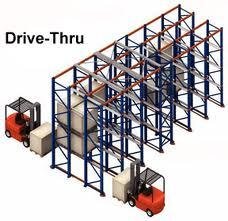

Unlike selective pallet rack where pallets are stored one deep, with Drive-in Rack, pallets are stored from 2-10 pallets deep. Drive-in rack is made up of rows of rack that the forklift drives into and stores the pallets on rails which are located on either side of the drive-in aisle. Guide rails on the floor help guide the forklift driver into the rack. Some attributes of Drive-In Rack are:

Provides greater storage density because there are fewer aisles than with selective pallet rack

Used in operations where there are many of the same type product (SKUs)

Allows for storage of products using a LIFO (last-in, first-out) storage method

Greater storage density than selective pallet rack because of the minimum number of forklift aisles needed

Used in operations where there are many of the same type product (SKUs)

Allows for storage of products using a LIFO (last-in, first-out) storage method

Greater storage density than selective pallet rack because of the minimum number of forklift aisles needed

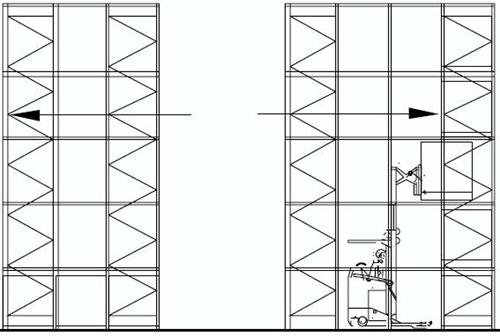

Another type of pallet rack which also utilizes a LIFO inventory storage system is Push Back Rack. One difference between Drive-In rack and Push-Back rack is Drive-In requires many pallets of the same SKU to be efficient, Push Back rack can be used in situations where there is as few as two pallets of the same SKU.